- +44(0)1487 833005

- [email protected]

- Unit A, Sawtry Business Park, Sawtry, Cambridgeshire PE28 5GQ

ACE CAPABILITIES

Engineering

We are managed and staffed by highly experienced engineering staff who can assist at all levels of the engineering process.

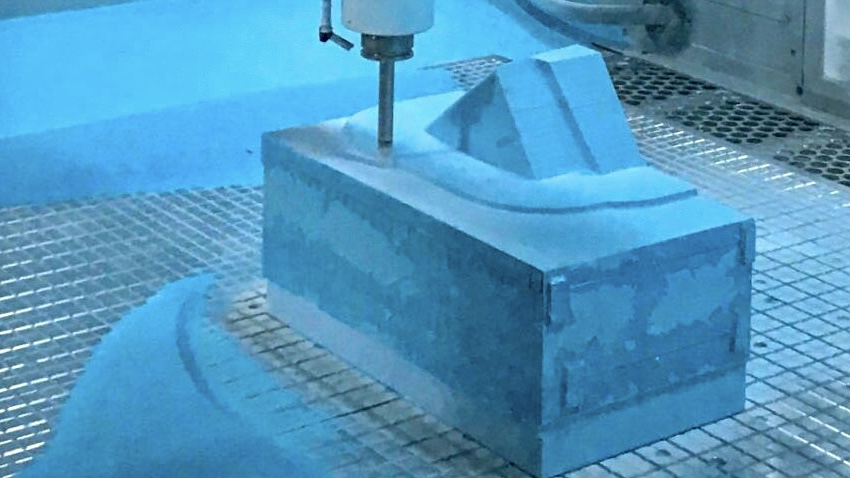

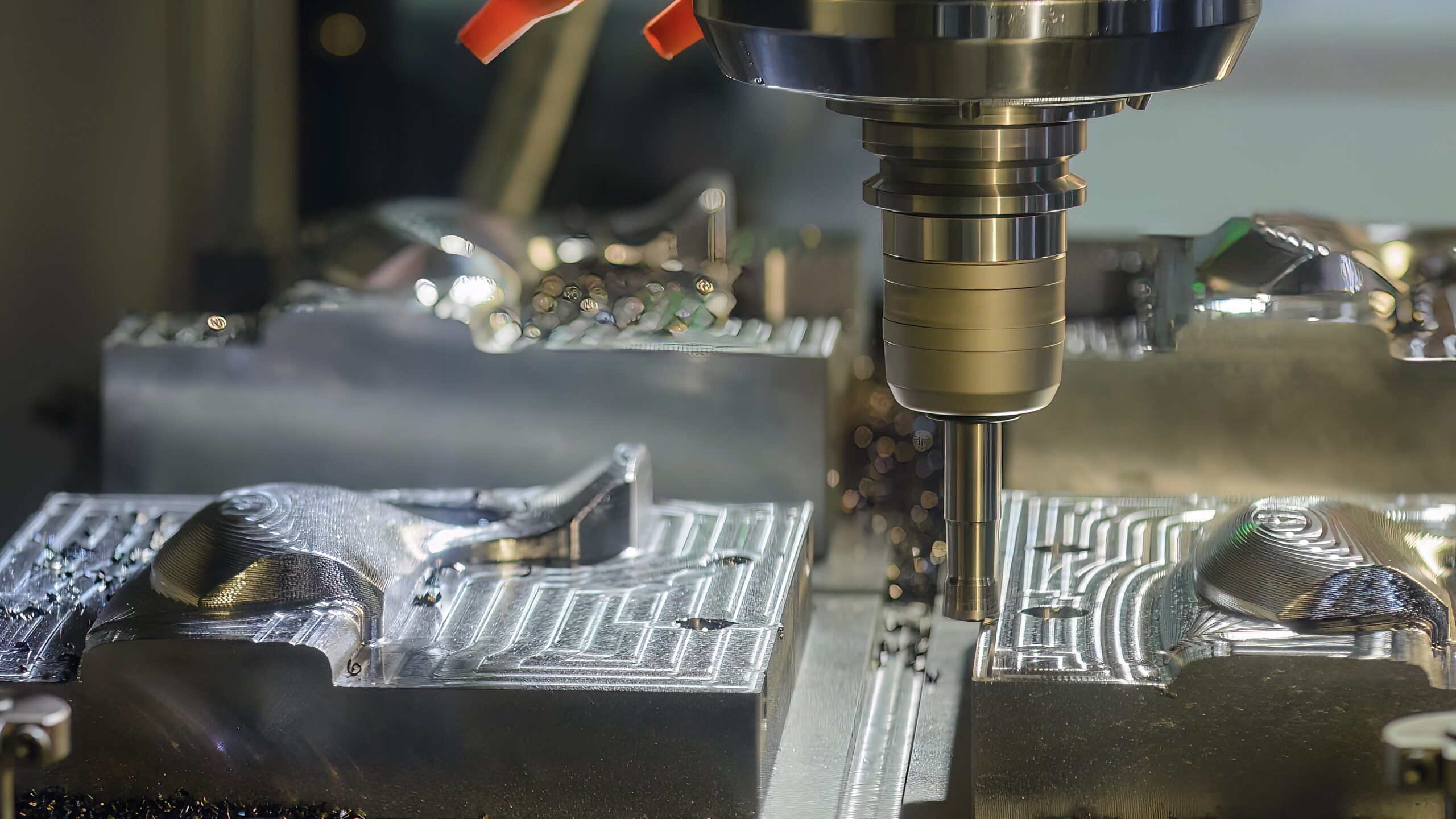

Pattern & Mould Design & Manufacture

ACE has decades of experience in composite tool design and manufacture. Whether the requirement is metallic or composite, ACE has the in-house capability for all types of tooling and process requirements.

Jig & Fixture Design & Manufacture

In-house design and manufacture for all types of jig and fixtures.

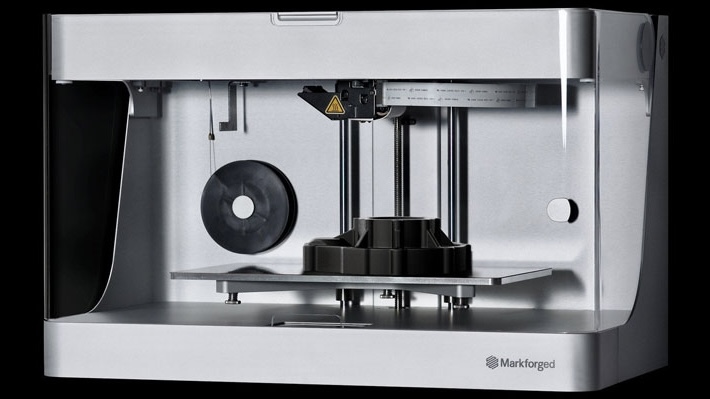

3D Printing

Markforged MK2 3D printer in-house capability 3D printer (Onyx/Fibreglass/Kevlar/Carbon printing capability)

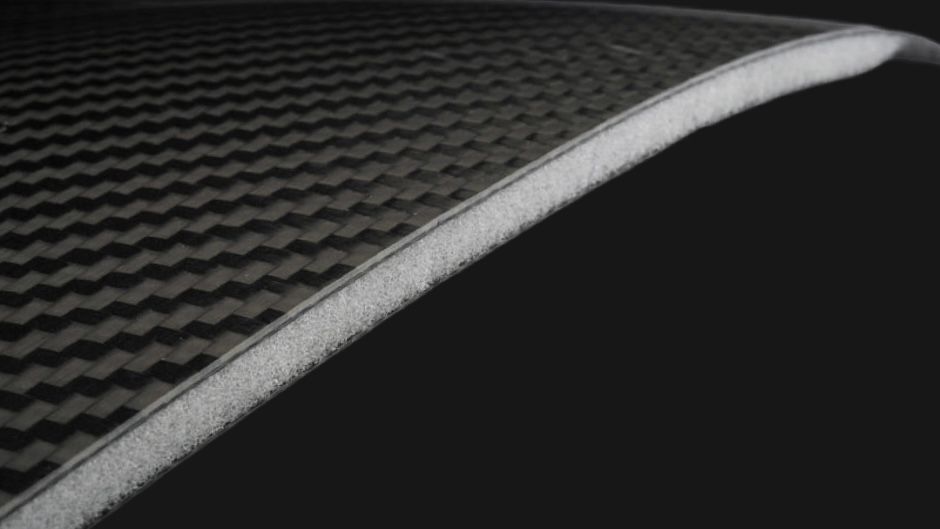

Carbon and Rohacell Machining

3 and 5 Axis in-house machining capability for cured carbon and all varieties of core types.

Automated Kit Cutting

CNC controlled material cutting.

1,000 ft2 State of art - Kit Cutting Room 2 (climate controlled) IECHO

750 ft2 Kit Cutting room 1 - Exact machine & digitiser

Pre-Preg Laminating

Clean room controlled laminating protocols for tooling and component parts.

Clean Room 1 - 2,200 ft2 (climate controlled)

Clean Room 2 - 750 ft2 (climate controlled)

Clean Room 3 - 1,500 ft2 (climate controlled

Autoclave Processing

5 full size Autoclaves.

Autoclave 1 - 1.3m x 3.5m 200oC 100psi

Autoclave 2 - 1.0m x 3.0m 200oC 100psi

Autoclave 3 - 1.1m x 1.5m 180oC 100psi

Autoclave 4 - 2.5m x 4.0m 250oC 145ps

Autoclave 5 - 1.5m x 3.0m 250oC 145ps

Belotti FLU 2617 CNC 5-axis machining centre X=2600, Y=1700, Z=1300mm, C= +/-270oC, A=+/-120oC (fully extracted)

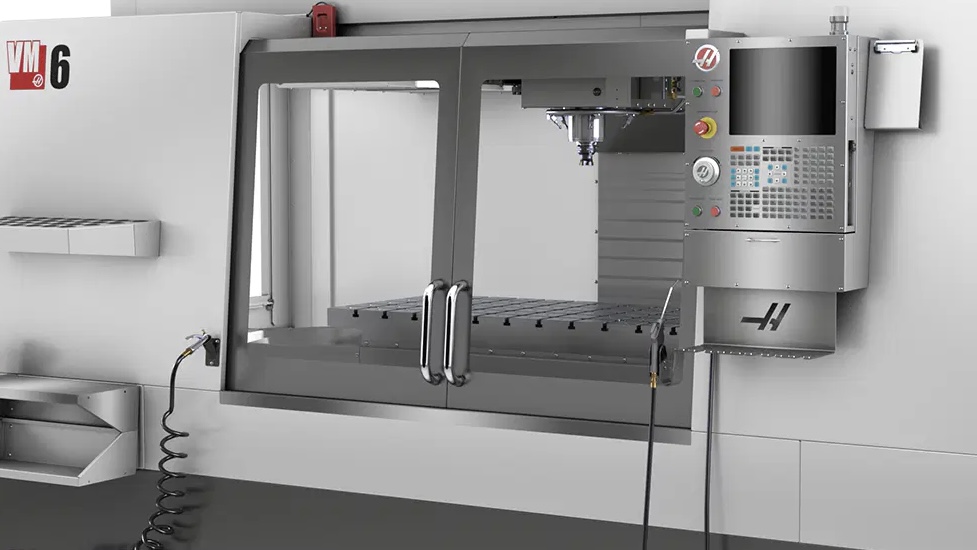

HAAS VM-6 CNC 3/4 axis vertical machining centre X=1626, Y=813, Z=762mm

HAAS TM-3P CNC 3/4 axis vertical machining centre X=1016, Y=508, Z=406mm

1.3m x 2.5m Precision CNC Machine (router)

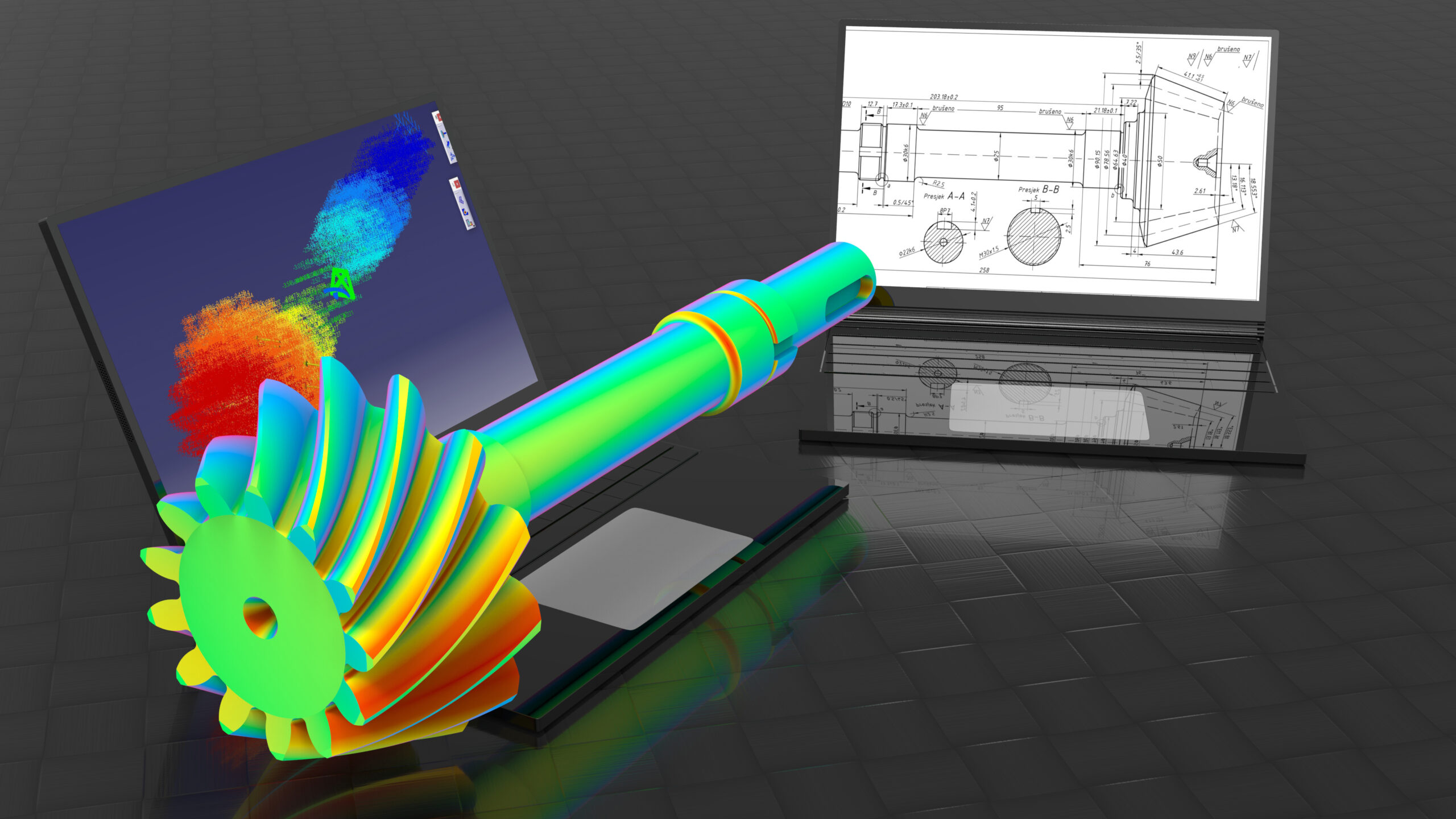

Solidworks/OneCNC/Autodesk - CAD/CAM

MetraSCAN750 & HandyProbe

Fully equipped Inspection room ISO9001: 2015